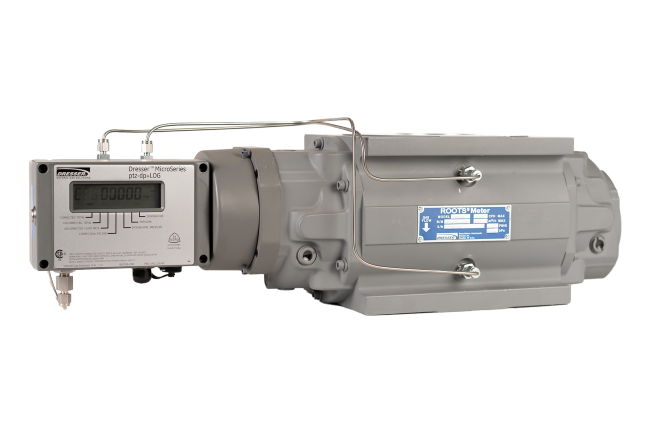

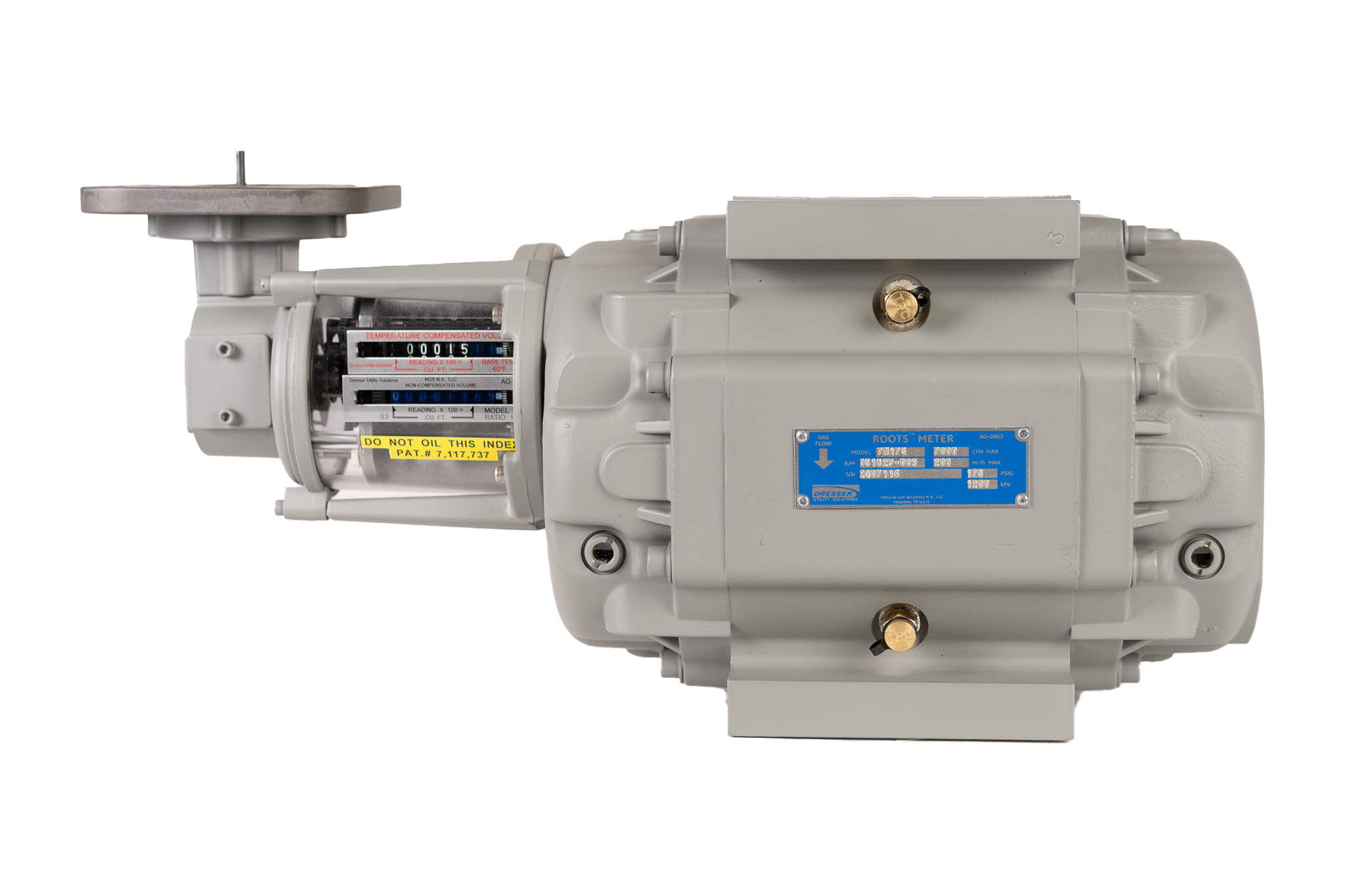

B Series 8C-56M ROOTS™ Meters

Measurement

Offering a Full Range of Sizes

Dresser Measurement offers a competitive range of ROOTS™ rotary meters for commercial and industrial metering applications, allowing for the selection of the correct meter size for cost effectiveness and accurate measurement.

Accurate Low Flow Performance

Low start/stop rates extend the rangeability (gas measured) over a wider range of flow conditions.

Standardized Flanges

- 8C/11C/15C size meters have a 6-3/4″ Flange to Flange dimension and 2″ ANSI 150 Flanged Connections for standardization in the meter set design. As loads change, meter sizes are easily interchanged, saving the cost of re-piping. Metric sizes are also available

- 5M175 size meters have a 6-3/4″ Flange to Flange dimension and 3″ ANSI 150 Flanged Connections in the meter set design.

- 7M175 size meters have a 9-1/2″ Flange to Flange dimension and 3″ ANSI 150 Flanged Connections in the meter set design.

- 11M/16M175 size meters have a 9-1/2″ Flange to Flange dimension and 4″ ANSI 150 Flanged Connections in the meter set design.

- 23M232 size meters have a 9-1/2″ Flange to Flange dimension and 4″ ANSI 150 Flanged Connections in the meter set design.

- 23M175 size meters have a 16″ Flange to Flange dimension and 6″ ANSI 150 Flanged Connections in the meter set design.

- 38M175 size meters have a 18″ Flange to Flange dimension and 6″ ANSI 150 Flanged Connections in the meter set design.

- 56M175 size meters have a 21″ Flange to Flange dimension and 8″ ANSI 150 Flanged Connections in the meter set design.

PRODUCT BRAND

Dresser Measurement