Overpressure Protection

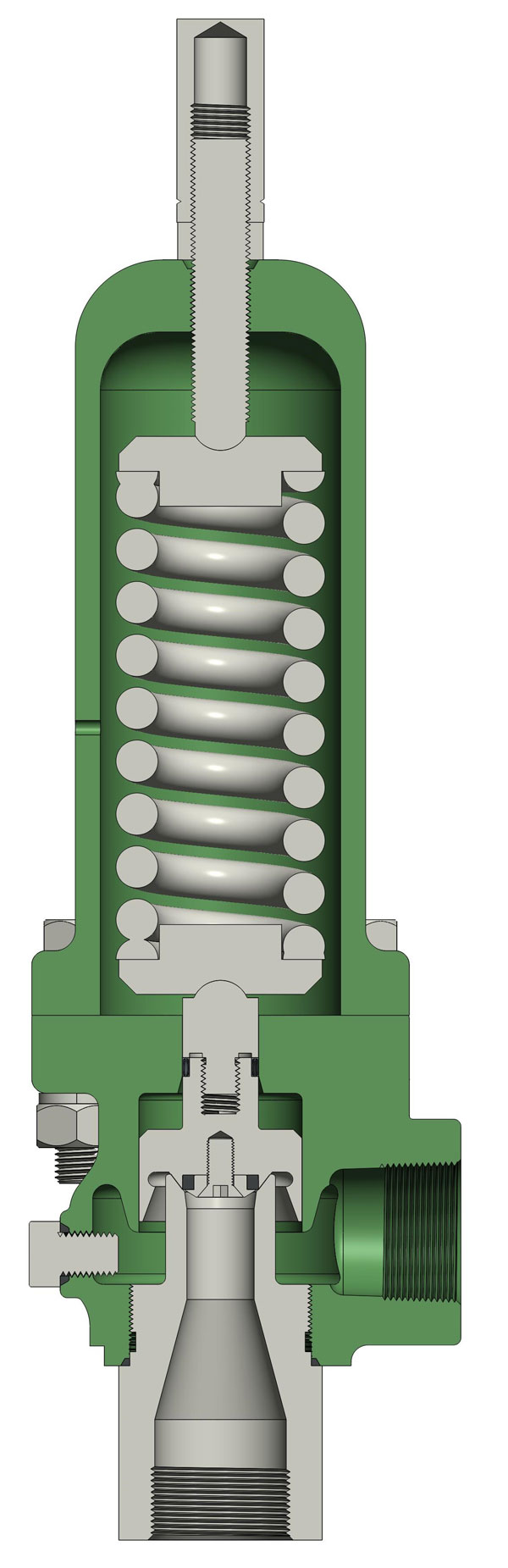

F88 (Balanced): Gas / Liquid / 2-Phase Service

Spring Operated Safety Relief Valves (ASME)

Balanced style SRV’s for gas, liquid, or mixed phase service. Balanced against the effects of backpressure without bellows. Made in accordance with ASME Section VIII or “CE” mark. Pop action on gas; initial modulation on liquid with fixed blowdown. Available in carbon or stainless steel materials as standard. Special alloy construction available upon request. Plastic seat/seals with various connection styles available.

FEATURES

- Spring-operated, snap-acting (gas) or modulating (liquid, low flow)

- Soft seated w/ backup metal-to-metal seat

- Fully balanced against backpressure without bellows

- Spring energizing V-seal for smooth operation

- Full lift: Gas = Set pressure, Liquid = 7.5% overpressure

- Leak tight seating and re-seating

- Fixed blowdown

- Integral / full nozzle, 316/316L corrosion resistant trim

- Packed lift lever available on most sizes

APPLICATIONS

- Variable gas or liquid service

- Mixed phase applications

- Cryogenic fluids

- Chemical processing

- Al plastic seat & seals for process compatibility

- nstallations with high outlet backpressures

Service Envelope

| Connection Sizes Custom sizes available on request | ½” x ½” - 2” x 3” (13mm x 13mm - 50mm x 75 mm) |

| Set Pressure Ranges See F88 Gas or Liquid Catalog for orifice specific ratings | 30 – 8,382 psig (2.1 - 578 barg) |

| Temperature Ranges | -423 to 400°F (-252 to 204°C) |

| Orifice Area Range | .065 – 1.689 in2 (41.9 – 1089 mm2) |

| End Connections Custom types available on request | Threaded: NPT, SAE, MS33649/AS5202, AN 37° Flare Welded: ASME / DIN / API / SAE flanged, Grayloc Specialty: Swagelok® Tube / VCR, Threaded & Coned |

| Materials of Construction Custom available for service or on request | Carbon Steel, Stainless Steel, Monel, Hastelloy C / C22 / C276, Duplex 22% or 25% Cr |

| Seat/Seal Materials Custom available for service or on request | Seat Material (Plastic): Teflon®, Ekonol-filled PTFE, Kel-F (PCTFE), PI/PAI (Vespel®, Duratron®, or equal), PEEK Spindle Seal Material (Plastic): Spring-energized Teflon V-Seal |

CERTIFICATIONS & COMPLIANCE

-

ASME Sec VIII Div. 1 (NB-18 Cert. No. 28044, 28055,28077, 28088, 28101, 28112, 28134, 28145)

-

API 520 (Sizing & Selection of PRV’s) / API 527 (Seat tightness of PRV’s)

-

Superior flow capability (KA factor) vs. equivalent API 526 orifice

-

API 526 center-to-face dimensions available on most sizes

-

NACE MR0175 H2S compliant materials available on request

-

PED / CE (2014/68/EU) compliant on request

-

Canadian CRN (all Provinces per CSA B51)

-

ABS Product Design Assessment (Cert. No. 15-HS1393800-PDA)

-

US Patent No. 7,513,270

PRODUCT BRAND

Flow Safe