Overpressure Protection

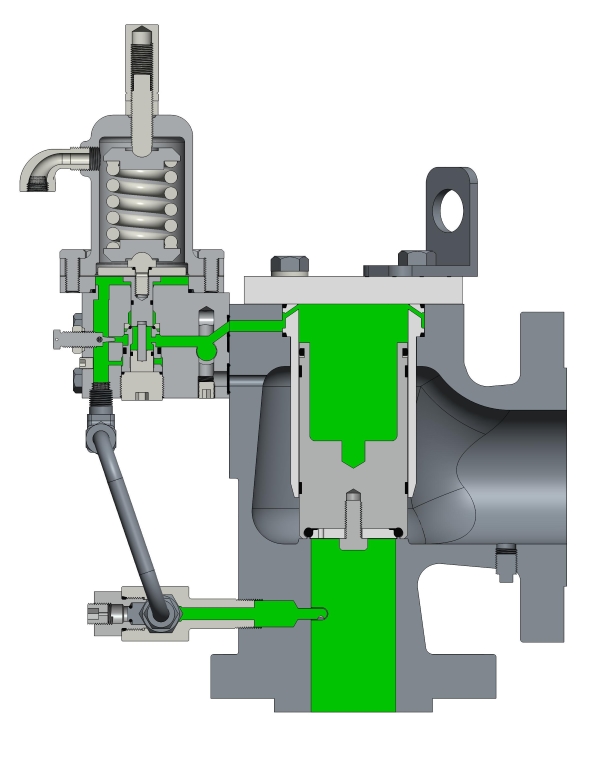

F7000/F8000 Pilot Operated Safety Relief Valve

FEATURES

- Choice of modulating or snap acting, flowing or non-flowing pilot

- Soft seated (Elastomer or Plastic)

- Backflow preventer & field test connection (quick-connect)

- Full bore (F7000) or reduced bore (F8000) orifice

- Full piston lift @ set pressure

- Pilot vents to process (F100, F300, F500) or atm. (F200)

- Leak tight seating and re-seating

- Integral flange design

- Integral nozzle (SS), 316/316L corrosion resistant trim

APPLICATIONS

- Ambient or cryogenic fluids

- Chemical processing

- High cycle rates / long service life

- Minimal product loss importance

- Operation close to set point with zero leakage required

Service Envelope

| Connection Sizes Custom sizes & dual outlet bodies available on request | 1” x 2” - 12” x 16” (25mm x 50mm - 300mm x 400 mm) |

| Set Pressure Ranges See F7000/8000 Catalog for orifice specific ratings | 15 – 6,000 psig (1.03 - 413 barg) |

| Temperature Ranges | -423 to 525°F (-252 to 274°C) |

| Orifice Area Range | .134 – 111.87 in2 (.86 – 72174 mm2) |

| End Connections Custom types available on request | Standard: Female NPT (1” x 2” & 1.5” x 3” size only) Integral ASME RF Flanged (up to 2500# inlet) Specials: DIN flanged (EN 1092-1), Grayloc, MS33649/AS5202 |

| Materials of Construction Custom available for service or on request | Carbon Steel, Stainless Steel, Monel, Inconel, Hastelloy C / C22 / C276, Duplex 22% or 25% Cr |

| Seat Materials Custom available for service or on request | F7040/F8040 Material (Plastic): Teflon®, Ekonol-filled PTFE, Kel-F (PCTFE), PI/PAI (Vespel®, Duratron®, or equal), PEEK F7050/F8050 Material (Elastomer): Buna-N, Viton® (FKM) or equal, EPR/EPDM, Aflas, FFKM (Chemraz®, Kalrez®, etc), Polyurethane, HNBR |

CERTIFICATIONS & COMPLIANCE

- ASME Sec XIII (NB-18 Cert. No. 28000, 28011, 28022, 28099, 28156)

- IGC Code Sizing (Air @ 0°C)

- BV Mode 1 & Type Approval

- DNV-GL Type Approval

- LR Design Appraisal Document F7100/8100, F8200, F8300, F8500

- US Coast Guard Certificate

- Cryogenic testing per ISO 21013:1(2008)

PRODUCT BRAND

Flow Safe

PRODUCT CATEGORIES

APPLICABLE REGIONS

Africa | Asia Pacific | China | Europe | Latin America | Middle East | North America | United Kingdom