WHAT WE DO

High Quality, Reliable Chemical Injection Technology

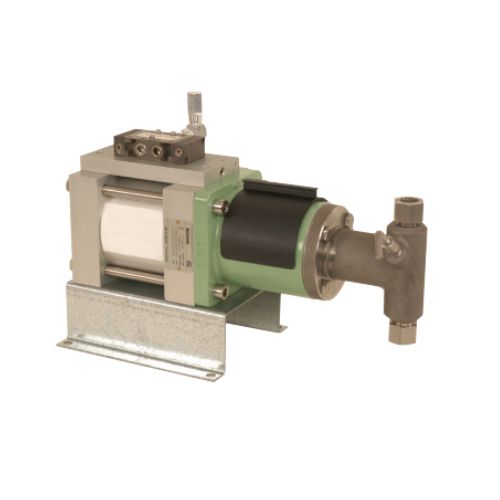

When you need to improve well production, inhibit system corrosion, or neutralize substances in your production stream, you need high quality, reliable chemical injection metering technology. Since 1938, Dresser’s Texsteam product line has offered a broad range of pneumatic, electric, and solar powered pump solutions that are designed to be plug-n-play, with easy installation and maximum life expectancy.

With more than 80 years’ experience designing and building reliable chemical injection metering pumps that are used in multiple industries ranging from Upstream, Midstream, and Downstream Oil & Gas, Municipal Water, Waste Water Treatment and Power Generation; Texsteam products can inject multiple fluids including but not limited to corrosion inhibitors, detergents, anti-foaming agents, methanol, and de-emulsifiers.

American made in Houston, TX, you can trust your operations to Dresser Chemical Injection and the Texsteam product offering.

Why Texsteam Chemical Injection?

Our Texsteam products are available to you for a wide range of chemical applications.

100% on-time delivery with reduced lead times.

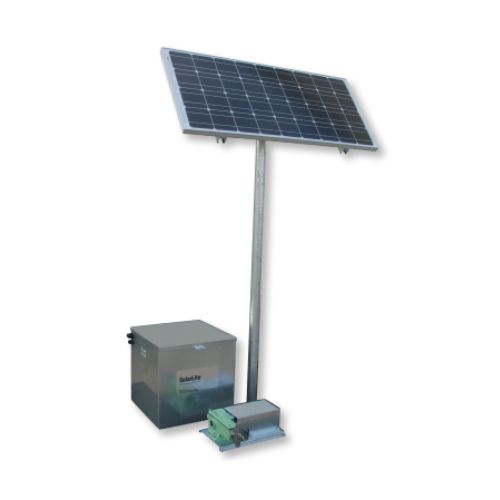

Full spectrum of solar kits, from entry-level to Division I Class II.

Low cost of ownership.

Little-to-no maintenance and no requirement of spare inventory on-hand.

Reduced downtime, reduced costs.

Search & Select a Chemical Injection Product

Select a product type, region or both. Or, search for the product by name. Once you’ve found what you are looking for, click the image or button to access product details.

HICIP

ICIP

Multipoint Injection Controller

Series 1200

Series 2200

Series 2400

Series 2500

Series 4300

Series 5000

Series 5100

Series 6100

Series 9000

Series MX-5

Series MXG

SolarLite

Dual-head Pumps Available.

Texsteam has introduced a new dual-head pump for Electric Pump Series 2200 and 2500 and on Solar Lite Pumps.

Our Commitment

Lowering Your Carbon Footprint.

Chemical injection pumps with zero emissions.