ASME Section XIII (“UV” stamped) enhanced performance direct spring-operated relief valve for gas/vapor service.

More Information On:

Flow Safe

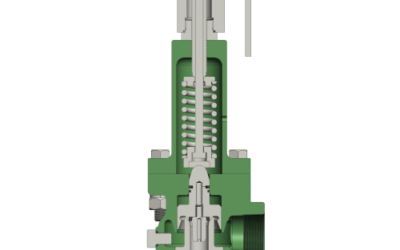

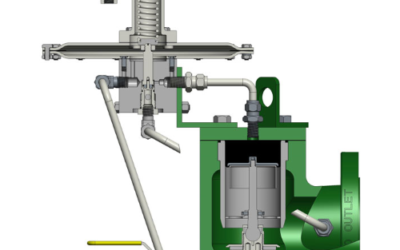

Direct Spring, Balanced – ASME code (F84L)

ASME Section XIII (“UV” stamped) enhanced performance direct spring-operated relief valve for gas/vapor service.

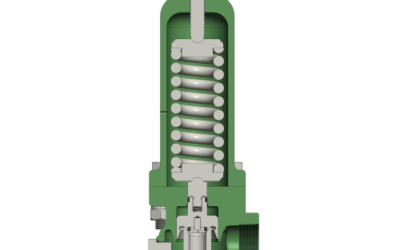

Direct Spring, Balanced – ASME code (F88)

ASME Section XIII (“UV” stamped) enhanced performance direct spring-operated relief valve for gas/vapor & liquid service.

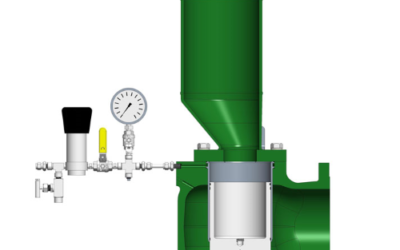

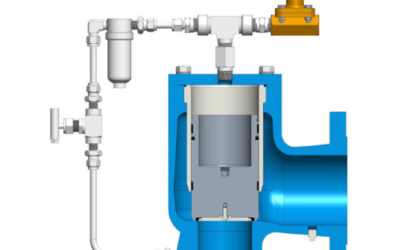

Liquid Surge (F9000)

The Flow Safe SurgeFlow series has been developed exclusively for liquid surge protection.

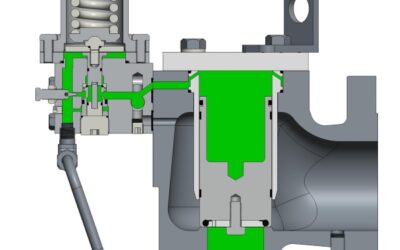

Pilot-Operated – ASME code (F7000/F8000)

ASME Section XIII (“UV” stamped) enhanced performance pilot-operated relief valve for gas/vapor & liquid service.

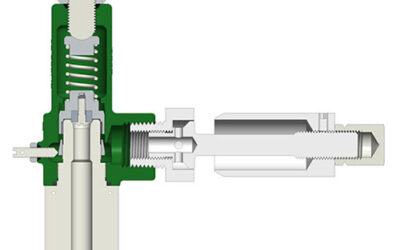

Pilot Operated (F70PR)

Enhanced performance pilot-operated relief valve designed for non-code applications, primarily the gas utility market.

Unloader (F70U)

Unloader valve provides a means to control flow for a variety of process flow applications, gas or liquid.

Safe-T Whistle

Flow Safe, Safe-T Whistle is designed to provide an audible signal of a system overpressure or upset condition, at a specific pressure.