Valve Automation

Cameron Valves

Cameron is a leading provider of valves, valve automation and measurement systems to the oil and gas industry. The following products are offered through Cameron:

- DEMCO Butterfly Valves

- DEMCO Resilient-Seated Butterfly Valves

- DEMCO Gate Valves

- WKM DynaCentric High-Performance Butterfly Valves

- WKM DynaSeal 210 and 310 Floating Ball Valves

- Fully Welded Ball Valves

- DEMCO Butterfly Valves

Cameron’s DEMCO butterfly valves are the valves of choice, engineered and proven for drilling and production industries. Designed for dependable, heavy-duty performance in abrasive and corrosive service conditions, DEMCO butterfly valves are commonly selected for several oilfield applications in the following industries:

- Chemical and Petrochemical

- Agriculture

- Oil and Gas Drilling and Production

- Food and Beverage

- Water and Wastewater

- Cooling Towers (HVAC)

- Power

- Mining and Materials

- Dry Bulk Handling

- Marine and Government

DEMCO Resilient-Seated Butterfly Valves

The DEMCO Resilient-Seated Butterfly Valve is an economic alternative to ball, gate or plug valves in many applications. They are lightweight quarter turn devices with few parts, designed for bubble-tight sealing up to rated pressure and are capable of throttling service. They are also easily adapted to automatic actuators, and are available in flangeless wafer design or single flange tapped lug configuration.

DEMCO Gate Valves

Cameron’s DEMCO gate valves are the valves of choice, engineered and proven for drilling and production industries. Designed for dependable, heavy-duty performance in abrasive and corrosive service conditions, DEMCO gate valves are commonly selected for several oilfield applications, including:

- Drilling Standpipe Manifold

- Pump Manifold Block Valves

- High-Pressure Mud Mixing Lines

- High-Pressure Drilling System Block Valves

WKM Dyna-Centric High-Performance Butterfly Valves

Cameron’s WKM® DynaCentric® high-performance butterfly valves bring a low-cost and lightweight solution to high-pressure water, oil, steam, gas and slurry applications. Engineered for heavy-duty, maintenance-free performance, the DynaCentric high-performance butterfly valve is most selected for the following applications:

- Chemical and Petrochemical Processing

- Utilities

- Pulp and Paper

- Oil and Gas Production

- Fuel Handling Systems

- Air Conditioning and Refrigeration

- Marine

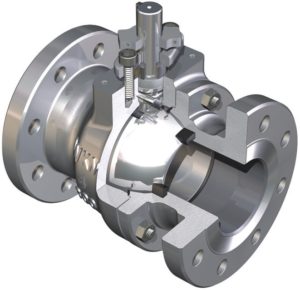

WKM DynaSeal 210 and 310 Floating Ball Valves

Cameron’s WKM® DynaSeal™ 210 ball valve is a two-piece design with a ductile iron body and tailpiece. This valve is economical and includes many of the premium design features found in the WKM DynaSeal 310 carbon steel ball valve.

WKM DynaSeal 310 floating ball valves satisfy a wide range of applications and are available in a variety of standard and optional materials, in sizes from 1/4” (8 mm) to 4” x 3” (100 mm x 80 mm) and working pressures to 5000 psi. Engineered for heavy-duty, maintenance-free performance, the DynaSeal 310 ball valve is preferred for use in critical applications.

Fully Welded Ball Valves

As one of the most trusted valves in the petroleum industry, the CAMERON fully welded ball valve combines the strength of forged components with a lightweight and compact spherical design. CAMERON fully welded ball valves satisfy ASME/ANSI 150 to 2500 (PN 20 to PN 420) and API 2000 to 5000 standards, and are used for a range of applications, including:

- Gas Transmission

- Product Pipelines

- Measurement Skids

- Dehydration Systems

- Gas Separation Systems

- Natural Gas Storage

- Dryer Service

- NGL Plants

- NGL Pipeline

- Compressor Stations

- CO2 Services

- Offshore

- Subsea